I. Introduction: Sourcing for Profitability, Not Just Visibility

In the complex ecosystem of the global retail supply chain, the role of a retail display extends far beyond visual merchandising. For wholesale buyers, sourcing managers, and brand procurement officers, a display rack represents a critical convergence of logistics optimization, manufacturing engineering, and total landed cost.

While the ultimate goal is to drive sell-through, the immediate challenge for the B2B buyer is to secure a fixture that balances structural integrity with supply chain efficiency. A visually stunning display that incurs exorbitant ocean freight charges due to poor volume optimization, or one that fails compliance checks (RoHS) at customs, is a liability.

This guide moves beyond basic retail definitions. Written from the perspective of Yishang Display, a custom manufacturer with over 26 years of export experience, we analyze retail displays by their manufacturing specifications, load-bearing physics, and logistical footprint. This framework helps you make procurement decisions that protect your margin and elevate your brand reputation.

II. Phase 1: The Engineering Diagnostic (The Procurement Checklist)

Before issuing a Request for Quotation (RFQ) or trying to find the right display for your rollout, experienced buyers define the technical parameters first. “Durability” is not a vague marketing term—it is a measurable engineering standard.

1. The Physics of Load & Material Selection

The most common failure point in OEM display manufacturing is a mismatch between the SKU weight and the material gauge. Procurement officers should categorize needs based on dynamic load capacity.

- High-Density Inventory (The Heavy Lifters): For heavy merchandise such as automotive parts, beverages, ceramic tiles, or hardware tools, standard tubing is insufficient. These applications require MIG-welded steel structures with reinforced gussets. Sheet metal thickness should typically range from 1.0mm to 2.0mm. Using under-spec material to save 5% on the FOB price often leads to a 20% failure rate in the field due to “metal fatigue.”

- Consumer Packaged Goods (CPG) & Lightweights: For snacks, apparel, or electronics accessories, the engineering approach shifts. Here, wire grid structures or lighter gauge tubing combined with acrylic elements offer the best balance of cost versus function. Optimizing the material usage to reduce tare weight without compromising stability is a key capability of a precision manufacturer.

2. Quick Comparison: Material ROI Matrix

To make a data-driven decision, compare the Total Cost of Ownership (TCO) across common materials:

| Feature | Corrugated (Cardboard) | Acrylic / Plastic | Powder-Coated Steel (Yishang Standard) | Wood / MDF Composites |

|---|---|---|---|---|

| Typical Lifespan | 2-8 Weeks | 1-2 Years | 5+ Years (Permanent) | 3-5 Years |

| Load Capacity | Low (<10kg) | Medium | High (100kg+) | High |

| Logistics Risk | High (Moisture damage) | High (Cracking) | Low (KD Design) | Medium (Heavy) |

| Best For | Seasonal Promos | Cosmetics / Tech | Auto Parts / Tools / Beverage | Wine / Apparel |

3. The Total Landed Cost Equation (Logistics Focus)

For an overseas buyer, the Ex-Works (EXW) price is deceptive. The real metric is the Total Landed Cost. The volume of the packaged display often impacts the final unit cost more than the raw steel price.

- The “Air” Problem: A fully assembled (welded) floor display is essentially shipping “air” in a container. Shipping assembled units might restrict you to only 80 units in a 40HQ container, skyrocketing per-unit freight costs.

- The Knock-Down (KD) Solution: Experienced manufacturers use 3D engineering to break complex structures into flat components. A robust KD design can increase container loading quantity (CLQ) by 300% to 400%.

Procurement Pro-Tip: Always ask your supplier for the “Packing Volume (CBM)” and “Loading Qty (40HQ)” during the design phase. A display designed for flat-packing directly improves your profit margin per unit.

4. Compliance & Surface Treatment Standards

When sourcing from China for export to the EU or US, regulatory compliance is a non-negotiable sourcing criterion.

- RoHS Compliance: Your supplier must certify that powder coatings and plating processes are free from lead, mercury, and cadmium. Failure here can lead to customs seizures. At Yishang Display, we integrate these checks into our QA process.

- Environmental Resistance: For displays destined for garden centers or coastal regions, specify Zinc-Phosphate pre-treatment before powder coating. This ensures the fixture passes the Salt Spray Test (ASTM B117), preventing rust that destroys brand image.

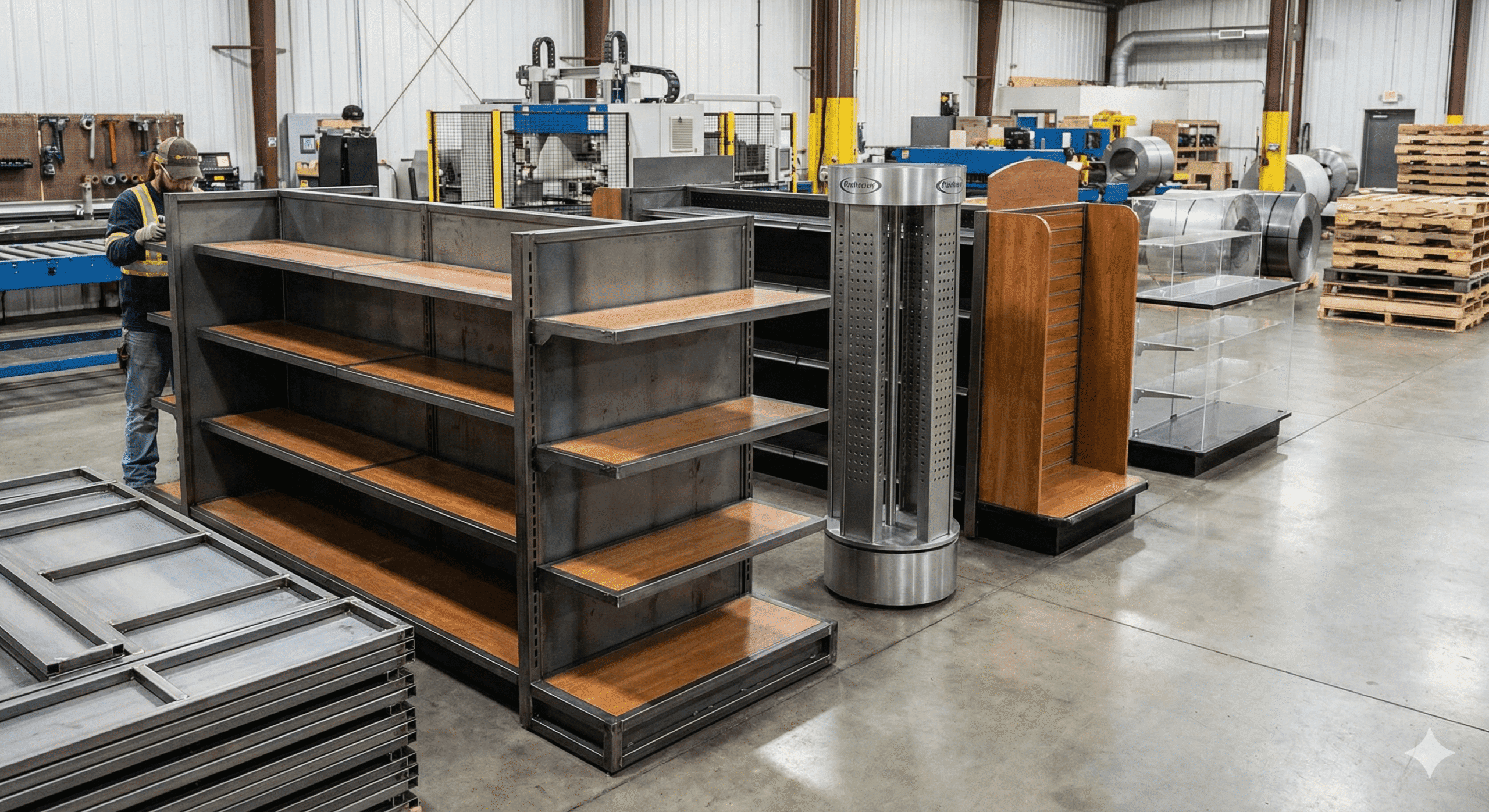

III. Phase 2: High-Volume Merchandising Solutions (The “Workhorses”)

These solutions are designed for inventory density. When you need to put product on the floor, these are your primary tools.

1. Gondola Integration & Inline Displays

While retailers usually provide the base gondola structure, brands must provide the “organization” to stand out. Sourcing custom gondola accessories is a high-volume business requiring precision manufacturing.

- The Sourcing Opportunity: Sophisticated buyers source Custom Branded Shelf Systems instead of generic dividers. These include spring-loaded pushers (auto-facing) that ensure product is always at eye level, magnetic vinyl overlays, and laser-cut metal headers.

- B2B Value: Inline displays are dense and ship efficiently. They allow your brand to “rent” space on the retailer’s shelf and dominate the visual field without paying for the entire structural footprint.

2. Free-Standing Floor Units (FSU)

The floor display is the autonomous salesperson. For B2B buyers, stability and ease of assembly are the primary concerns.

- The Spinner Rack (Rotary Display): Look for industrial-grade ball bearings at the pivot point rather than plastic washers. Bearings ensure smooth rotation for years, defining “commercial grade” quality. These are great for new products that need visibility from all four sides.

- Assembly Check: A well-engineered spinner rack should allow store staff to quickly assemble them in under 10 minutes (tool-free). Complex assembly leads to displays being discarded in the backroom. Talk to a display engineer to ensure your design prioritizes “Ease of Assembly.”

- Custom Metal Towers: Utilizing CNC laser cutting to create unique silhouettes (e.g., a bottle shape) allows your product to stand out in a crowded aisle. Once the tooling is created, the unit cost drops significantly for volume orders.

3. Pallet Displays & Case Stackers (Warehouse Club Format)

For channels like Costco or Sam’s Club, the display is the shipping container.

- The Hybrid Strategy (Steel + Corrugated): Full corrugated pallets often crush under warehouse humidity. The smart B2B solution is Metal Pallet Skirts/Guards. Source a durable, branded metal base that protects the corners.

- Sustainability: The cardboard trays are replaceable, but the metal “armor” ensures the brand looks premium. A full pallet dressed in metal commands authority and is easy to move with a pallet jack without structural failure. Properly engineered displays pallet displays withstand the weight of food and beverage bulk packs without collapsing.

IV. Phase 3: Traffic Interception & Cross-Selling

These fixtures are designed to disrupt the shopper’s journey. For the wholesaler, these are high-margin value-add items that can be pitched to retailers as revenue boosters.

1. Custom Endcap Fixtures

Standard endcaps are functional but generic. Custom fabricated metal endcaps are high-impact billboards positioned at the ends of aisles.

- Construction: These are typically heavy-duty, fully welded frames designed to replace standard shelving entirely. Because they face the main “racetrack” of the store, they must be sturdy enough to withstand constant cart impacts.

- Modular Engineering: A smart manufacturer designs the endcap with adjustable slot spacing to accommodate future product packaging changes. This “future-proofing” extends the asset’s life—a key selling point when pitching to retailers.

2. Power Wings and Sidekick Displays

The ultimate cross-merchandising tool. Power wing and sidekick units utilize “dead space” on the side of shelving.

- Universal Attachment Logic: The biggest sourcing headache for Power Wings is compatibility. Ensure your manufacturer engineers a “Universal Bracket” system. The same display should mount to standard US pegboard, slatwall, and wire grids.

- Usage: They are an excellent choice for small, high-margin items like health and beauty products or batteries. You can stock a significant amount of inventory in a zero-footprint space.

V. Phase 4: Point of Purchase (POP) Precision

The checkout zone requires high finishes and theft deterrence.

1. Countertop Units (Acrylic & Metal Hybrid)

When considering displays counter displays, remember that counter space is the most expensive real estate in the store.

- Material Strategy: Pure acrylic is brittle; pure metal is industrial. The ideal B2B solution is a Metal Sub-structure (strength/cost savings) with Acrylic Cladding (aesthetics). This hybrid approach reduces breakage during shipping—a massive hidden cost in acrylic procurement.

- Counter Shipper vs. Permanent: A counter shipper (temporary cardboard) is an expense; a permanent unit is a capital asset. For long-term ROI, invest in permanent hybrids that retailers can refill for years.

- Security Integration: For high-value items, request integrated locking mechanisms or tether anchors in the design phase.

2. Promotional Dump Bins

A dump bin is a bulk container designed for irregularly shaped items.

- The Durability Upgrade: Specify collapsible wire baskets with an adjustable bottom shelf. Displays not sure of inventory levels benefit from adjustable bottoms that keep products looking full even as stock depletes.

- Logistics: These must fold completely flat. A collapsible design allows fitting thousands in a container, dramatically lowering the landed cost per unit compared to rigid bins. Display bins and baskets are essential for clearing seasonal inventory.

VI. Phase 5: Strategic Design & Integration

Successful procurement involves looking at the bigger picture. A display does not exist in a vacuum; it must integrate with packaging and information flow.

1. Integrating Display and Packaging Design

Your product packaging dictates the display engineering. If your packaging design changes, the display might become obsolete.

- Optimization: We recommend adjustable channel widths and universal hooks. By analyzing your packaging dimensions early, we can ensure the center of gravity remains low and the shelf density is maximized.

2. Brochure Holders & Retail Signage

Displays brochure holders and retail signage are critical for complex tech or industrial products.

- Metal Integration: Instead of attaching a fragile plastic holder, Yishang Display integrates metal pockets directly into the laser-cut frame. This looks more premium and prevents breakage. Displays retail signage frames can be designed for easy graphic swaps, allowing campaign updates without replacing hardware.

VII. Why Partner with an OEM/ODM Specialist?

For the wholesale buyer, the choice of factory is a strategic partnership. It is not just about the lowest welding cost, but about understanding the global supply chain.

Design for Manufacturing (DFM)

A true ODM partner takes your design concept and applies DFM principles. We analyze:

- Can we reduce the steel gauge without losing strength?

- Can we change a weld to a bolt to reduce packaging volume by 40%?

- Can we nest parts to maximize material yield?

This engineering value engineering (VE) is where real profit is generated.

Scalability & Quality Assurance (QA)

Sourcing 50 units is easy; sourcing 10,000 units requires robust process control. Yishang Display adheres to ISO 9001 standards, ensuring that unit #10,000 is identical to unit #1, reducing the risk of batch rejections. Whether you need a specific RAL color match or a unique material combination, our facility handles it all.

VIII. Frequently Asked Questions (FAQ)

Q: What is the most durable material for retail displays? A: Powder-coated steel is the gold standard for durability. Unlike cardboard or wood, it resists moisture, heavy loads, and impact, making it ideal for permanent retail fixtures.

Q: How does Knock-Down (KD) design affect shipping costs? A: KD design breaks the display into flat components. This can increase container loading quantity by 300-400%, significantly reducing the per-unit shipping cost compared to pre-assembled units.

Q: What is the difference between POP and POS displays? A: POS (Point of Sale) refers specifically to the checkout counter area (impulse buys). POP (Point of Purchase) is a broader term encompassing any location where a buying decision is made, including aisles and endcaps.

IX. Conclusion: Elevating Your Supply Chain

In the B2B world, a retail display is an asset class. Its value is determined by its Total Cost of Ownership (TCO)—from the factory floor, through the ocean container, to the ease of assembly in the store, and finally, its longevity on the shelf.

Sourcing “cheap” displays often results in expensive logistics problems. Sourcing engineered solutions results in supply chain efficiency and retail dominance.

Yishang Display is not just a factory; we are your supply chain partner. We deliver displays that are engineered to ship efficiently, assemble effortlessly, and sell effectively.

Optimize your next procurement project. Contact our engineering team today for a DFM analysis.