Your Signage Isn’t an Expense, It’s an Asset—But Are You Building It Correctly?

For wholesale purchasers and distributors, the choice of signage technology extends far beyond aesthetics. It is a strategic decision that directly impacts inventory management, logistics, client satisfaction, and long-term profitability.

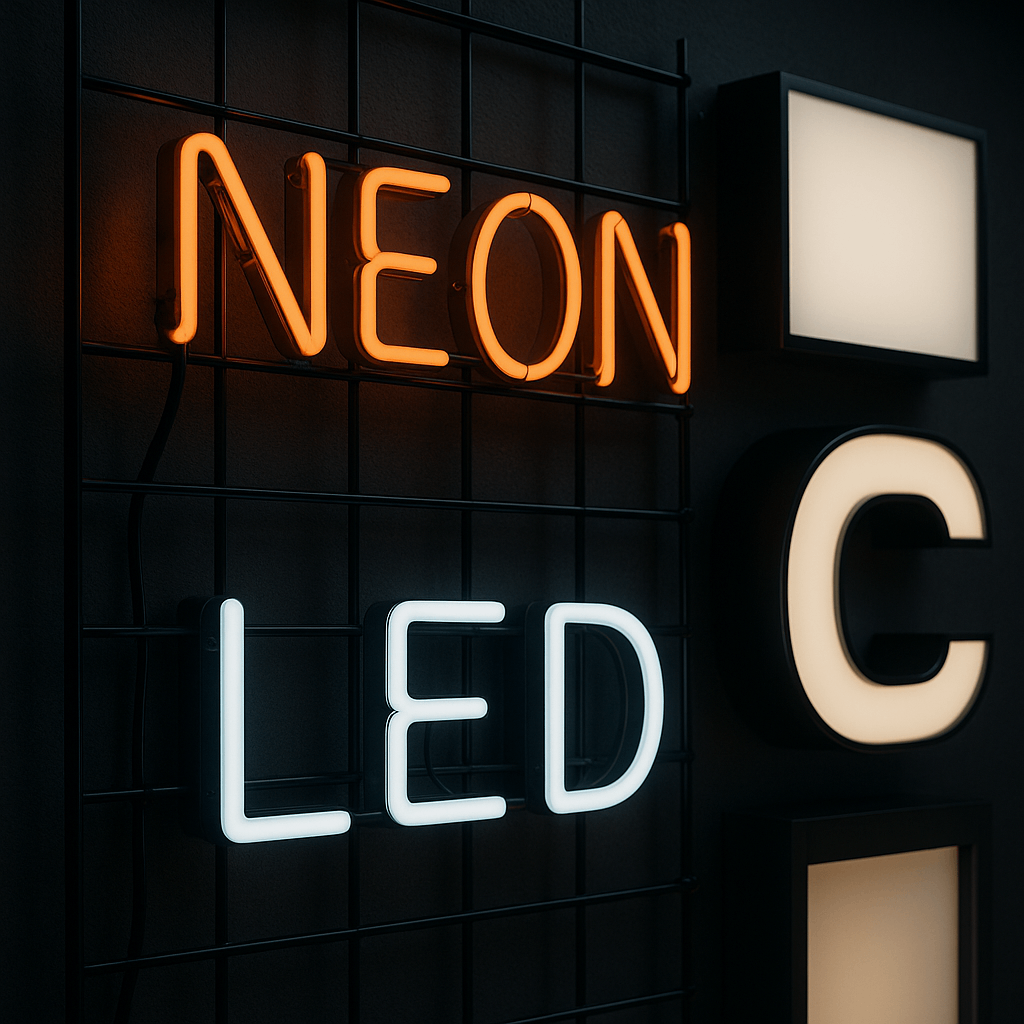

The debate between traditional neon and modern LED is not merely about a light source. It is about investing in a complete product ecosystem. The light source is the “heart,” but the structural framework—the metal housing, brackets, and custom display systems—is the “skeleton.” A failure in either component compromises the entire asset, leading to costly returns and reputational damage.

This guide moves beyond the simplistic “which light is better” debate to provide a comprehensive commercial signage strategy framework tailored for B2B decision-makers. As specialists in the engineering and fabrication of commercial display structures, we at Yishang Display dissect this choice from the perspective of a supply chain partner, helping you build a more reliable and profitable product line.

We analyze the quantifiable financial realities through a rigorous ten-year Total Cost of Ownership (TCO) audit. We explore the critical engineering truths of how a light source dictates the design, durability, and scalability of its physical housing. Finally, we examine how to deliver a synergistic package of light, structure, and brand story that empowers your clients.

60-Second Decision for Procurement Professionals: The Data-Driven Verdict

In the world of wholesale and distribution, time is a critical resource. For professionals who require a clear, data-backed conclusion to inform procurement strategy, this is the executive summary.

The historic rivalry between neon and LED is, from a technical and financial standpoint, decisively over. Across every key performance indicator relevant to a scalable business model, one technology presents an undeniable, quantifiable advantage.

Neon vs. LED: Key Performance Indicator (KPI) Showdown for Wholesale Distribution

| MetricTraditional Glass NeonModern LEDThe Decisive Winner & B2B Implication | |||

|---|---|---|---|

| 10-Year Total Cost of Ownership (TCO) | ~$26,970 ¹ | ~$3,479 ¹ | LED (by ~87%). A vastly superior long-term value proposition to offer your clients. |

| Energy Efficiency (Power/Meter) | ~65 Watts ² | 4–13 Watts | LED (~10x more efficient). A key selling point for eco-conscious and cost-sensitive end-users. |

| Effective Lifespan (Hours) | ~10,000 ⁴ | 50,000–100,000+ ⁴ | LED (5–10x longer). Drastically reduces client complaints, returns, and warranty claims. |

| Structural Dependency & Weight | Fragile, heavy glass requires robust, costly housing ⁹ | Lightweight, flexible polymer integrates with efficient, minimalist structures | LED. Lower shipping costs, reduced risk of transit damage, and simpler installation for clients. |

| Safety & Liability Profile | High Voltage (up to 18kV), breakable glass, contains mercury | Low Voltage (12/24V), shatterproof, non-toxic | LED. Significantly lower liability risk for both distributors and end-users. |

| Scalability & Customization | Bespoke, manual craft; difficult to scale consistently ⁹ | Modular components; ideal for mass customization and standardized production. | LED. Enables efficient manufacturing workflows and consistent quality across large orders. |

| Future Technology Compatibility | Analog technology; a static, information island. | Digital platform; ready for AI & IoT integration ¹² | LED. Offers an upgrade path and future-proof value, a powerful competitive differentiator. |

The data is unequivocal. For any business operating on a wholesale model that values reliability, scalability, and long-term client satisfaction, LED technology is not just an alternative; it is the foundation of a modern, profitable, and sustainable product line.

In-Depth Analysis: The Three Dimensions of Light, Cost, and Structure

To build a truly resilient product offering, a supplier must understand the technology from first principles. This requires a multi-dimensional analysis that moves beyond marketing claims to examine the core physics, the long-term financial implications, and the crucial interplay between the light source and its physical structure.

Financial Audit: Uncovering the Hidden Ten-Year Ledger of Your Signage

For a procurement manager, the unit cost is only the beginning of the story. A comprehensive signage cost analysis based on a Total Cost of Ownership (TCO) model reveals the true financial landscape, providing the data needed to justify investment and educate clients on long-term value.

The initial investment for a traditional neon sign is substantially higher, a direct result of the artisanal, non-scalable labor required for glass bending. This is compounded by complex installation logistics. Due to its high-voltage nature (up to 18,000 volts) and extreme fragility, neon necessitates specialized electricians and careful handling, adding significant and often unpredictable costs for the end-user.

In contrast, LED signs leverage the efficiencies of mass-produced components. Their safe, low-voltage (12V/24V) system not only lowers the purchase price but dramatically simplifies installation, reducing the end-user’s reliance on costly specialist contractors.

The most significant financial divergence, however, is found in operational expenditure. A typical neon sign consumes nearly ten times more energy than an equivalent LED sign—a critical data point for any client concerned with rising energy costs. Over a decade, this differential translates into thousands of dollars in electricity costs.

Neon signs are also high-maintenance, requiring professional service to address gas leaks, transformer failures, and inevitable tube breakages. This creates a recurring and unpredictable cost for the owner. LED signs, being solid-state and modular, are virtually maintenance-free.

When all these factors are compiled into a ten-year financial model, the conclusion is powerful. An end-user can expect to save over $23,000 by choosing LED—a capital saving that allows them to invest in higher-quality metal display stands or other business-critical areas. For a wholesaler, this is not just a product feature; it is a compelling ROI argument to present to every client.

Engineering Reality: How the Light Source Dictates Its “Skeleton”

This is the critical, often-overlooked dimension where the choice of light source directly impacts the physical world of materials, fabrication, and logistics—the core of our business at Yishang Display. The signage structure engineering required for neon and LED are fundamentally different, affecting design potential, shipping costs, and long-term durability.

Fragility and Structural Burden of Neon

Traditional neon is defined by its fragility. The hand-bent glass tubes are highly susceptible to breakage from impact and vibration, a major liability during shipping and installation. This inherent vulnerability, combined with the significant weight of the glass and high-voltage transformers, imposes severe constraints on the supporting structure.

To ensure safety and stability, neon signs demand robust, often bulky and heavy, metal sign frames and protective enclosures. This increases material costs, complicates the fabrication process, and limits aesthetic possibilities. For a distributor, this means higher shipping weights, increased packaging costs, and a greater percentage of loss due to transit damage.

LED: A Lightweight Shift in Design and Logistics

LED technology liberates signage from these physical constraints. Modern LED neon flex is housed in durable, lightweight PVC or silicone, making it inherently shatterproof and resilient. This dramatic reduction in weight and fragility revolutionizes LED signage housing design for outdoor and retail settings.

It allows for elegant, efficient, and minimalist custom literature displays, slender aluminum channel letters, and seamless integration into modern architectural elements. The design freedom is immense, enabling light to be incorporated into intricate patterns and curved surfaces that would be impossible with neon.

Practical Gains for Wholesalers and Outdoor Deployments

For wholesalers, this translates directly to lower shipping costs, reduced transit damage, and the ability to offer a wider range of modern, lightweight designs that are easier for clients to install. Furthermore, for outdoor applications, high-quality LED systems with IP67 ratings for water and dust resistance, when paired with corrosion-resistant metal structures like stainless steel or powder-coated aluminum, create a holistic, low-maintenance, high-durability solution—a product that builds client trust and minimizes post-sale issues.

The Aesthetic Debate: Can the “Retro Vibe” Be Technologically Replicated?

The most passionate defense of traditional neon centers on its unique aesthetic—the warm, 360-degree ambient glow that has become a cultural icon. For decades, this “authentic vibe” was something LED technology, with its directional, often harsh point-of-light sources, could not truly match.

Recent technological advancements have largely rendered this debate obsolete. The advent of COB (Chip-on-Board) LED technology has been a game-changer for neon aesthetic replication. Unlike older SMD LEDs that produced visible “dots” or “hotspots,” COB technology mounts hundreds of micro-LEDs directly onto a flexible circuit board, creating a perfectly uniform, seamless line of light.

This “dotless” output masterfully mimics the continuous glow of a traditional neon tube, capturing its visual essence without the physical or financial drawbacks. It enables clients to achieve the classic look, backed by the superior performance and reliability of modern technology.

While neon signs are locked into a single color, LED signs are dynamic. Through RGB programming, one LED sign can produce millions of colors, execute transitions, create animations, and even sync with audio or data inputs. This transforms a sign from a static marker into an interactive brand communication tool that traditional neon simply cannot match.

Strategic Application: What Industry Buyers Actually Need

Understanding the technology is crucial, but aligning it with real-world business contexts is what transforms a product into a scalable solution. Across industries, buyers face distinct operational, compliance, and branding demands. Therefore, the optimal signage system is not defined by one-size-fits-all specs, but by its adaptability to specific industrial needs.

Retail chains, for example, demand scalable signage that installs quickly across multiple locations. Here, LED’s lightweight structure and low-voltage wiring enable faster rollouts, while RGB programmability allows localized visual themes. When paired with Yishang’s modular metal display rack systems, the outcome is a replicable, installation-friendly program that accelerates time-to-market.

In hospitality and F&B, durability and ambiance must coexist. High-traffic environments like bars and restaurants require signage that can withstand moisture, heat, and cleaning routines while maintaining brand elegance. With LED housed in IP-rated enclosures and mounted in custom powder-coated steel frames, it’s possible to deliver long-life performance without compromising aesthetics.

Automotive showrooms and hardware retailers prioritize structural stability. In these rugged environments, fragile neon simply isn’t viable. Instead, LED systems built into metal-framed freestanding displays offer strength, clean lines, and support for dimensional logos or part outlines, meeting both branding and operational durability requirements.

In every case, LED is not just an illumination tool—it becomes an engineering element within a broader visual merchandising system. And when integrated into precision-built structures, the result is a durable, scalable, and application-specific solution ready for volume deployment.

LED as a Platform: Future-Proofing Signage Procurement

Beyond efficiency and design, LED technology uniquely enables integration with emerging commercial technologies. Neon, by nature, is a fixed analog light source. In contrast, LED operates as a programmable, digital interface, ready to support interactive, data-driven retail ecosystems.

Forward-looking procurement teams increasingly value systems that evolve over time. LED signage supports this through smart features like:

- Remote brightness and color control for seasonal adjustments

- Sensor-based interactivity, responding to motion or ambient conditions

- API connectivity for integrating signage into centralized retail dashboards

Such capabilities convert signage from a passive fixture into a responsive brand asset. Even if clients are not ready to deploy these systems today, LED’s open architecture ensures that investments made now won’t be obsolete when digital signage expectations grow.

At Yishang, our expertise in custom sheet-metal enclosures ensures that smart LED hardware can be physically accommodated: venting for active cooling, compartments for control units, and shielding for signal protection—all available at OEM scale.

LED is thus not only the better light source for today, but the future-compatible foundation for connected retail and industrial display systems.

Conclusion: Structure + Light = Competitive Advantage

Choosing between neon and LED is not simply a matter of price or brightness. For B2B buyers—especially those responsible for brand rollouts, international procurement, and volume deployment—it is a decision about risk, scalability, and engineering compatibility.

LED wins on:

- Cost Efficiency — From initial pricing to ten-year ownership models.

- Structural Compatibility — Lightweight, durable, and safer for transport and installation.

- Brand Flexibility — Programmable light profiles and color dynamics.

- Future Readiness — Digital infrastructure compatibility.

At Yishang Display, we support these benefits not by selling LEDs—but by designing and producing the metal structures that make LED signage durable and scalable. From signage enclosures to integrated retail display solutions and standalone illuminated kiosks, we offer OEM and ODM solutions grounded in 26+ years of engineering expertise.

If you’re upgrading legacy signage systems, launching new display programs, or seeking a reliable supplier for structural LED integration, we invite you to consult with our team.

Let’s build signage systems that work today—and evolve tomorrow. Contact us for a custom quotation or structural review.