Beyond the Price Tag: What You're Really Buying With a POP Display

When international buyers search for POP display solutions, the first number that often comes up is unit price. But for experienced wholesale buyers managing volume procurement, cost-effectiveness is about more than a quote figure. The real value of a custom POP display lies in how it supports sell-through, resists shipping damage, and simplifies retail execution.

At Yishang Display, we’ve delivered over 1,200 POP display designs to clients in 50+ countries. From cosmetics to automotive parts, our clients consistently confirm that lifecycle performance matters more than upfront pricing. A $90 floor stand reused across three seasons will outperform a $35 display that warps or fails within weeks.

Procurement teams increasingly ask not only “what is a POP display” but “what return will it generate?” That’s the question this article answers.

YISHANG is a China-based OEM manufacturer specializing in metal retail shoe display shelves for global wholesale buyers. With over 26 years of manufacturing experience, we design engineered display systems that combine durability, brand consistency, and spatial efficiency.

When customers step into a retail space, their perception starts before interaction. The layout, materials, and even how shoes are arranged shape their buying mindset. In this context, a shoe display shelf isn’t just a fixture—it’s brand communication. Whether showcasing premium sneakers or organizing seasonal sandals, a well-planned display speaks directly to how your brand values the customer experience.

In a crowded retail environment, your shoe store display must do more than hold inventory. It needs to boost visibility, support traffic flow, and drive conversions. YISHANG delivers solutions engineered for commercial performance and tailored to the visual and practical demands of global retail environments.

Core Cost Drivers: Understanding What Affects POP Display Pricing

As a POP display manufacturer serving the B2B sector, we help buyers understand where their investment goes. Five primary drivers influence pricing:

Materials: From corrugated POP displays to powder-coated steel, the selection directly affects durability, perceived quality, and shipping cost. We helped a fitness retailer cut costs 18% by engineering a switch from solid panels to steel mesh—without compromising visual impact.

Display Type: Freestanding display units (FSDUs), endcap fixtures, and pop up exhibition designs require more structure and finishing than countertop inserts. Complexity scales cost.

Design Complexity: Buyers often seek collapsible frames, pop signage, or modularity. These add prototyping and tooling requirements. One U.S. beverage client saw claims drop 40% after we introduced anti-tip reinforcement in their display structure.

Customization Scope: Full branding integration, such as PMS-matched finishes or custom embossing, adds value but also tooling and QA needs. We often recommend a semi-custom approach for orders under 1,000 units to balance brand goals with cost.

Shipping Format: Pre-assembled units ease store setup but cost more to transport. Our knock-down designs reduce container volume by 30–35%, ideal for overseas distribution.

This section addresses not just “POP display cost” but why that cost varies depending on specs, compliance, and usage goals.

Price Benchmarks That Matter in Real-World Projects

Procurement decisions require reliable benchmarks. Below is a practical matrix of pricing from projects we’ve delivered:

| Display Type | Material | Use Case | Estimated Price (USD) |

|---|---|---|---|

| Countertop | Cardboard | Temporary promos, shoppop displays | $5–$30 |

| Freestanding (FSDU) | Metal/Wood | Category rebrands, retail campaigns | $80–$300+ |

| Endcap Fixture | Mixed | Beverage, CPG seasonal rollouts | $100–$400+ |

| Acrylic Shelf Insert | Acrylic | Health & beauty, electronics | $20–$150 |

We recently supported a European distributor who reduced unit cost from $18.90 to $14.85 on a 2,500-piece order of corrugated POP displays through optimized carton sizing and modular shelf design.

Indirect Costs: Often Ignored, Always Impactful

While unit price matters, smart buyers look at total landed cost. Here’s where hidden expenses can erode your margin:

Assembly Labor: Displays that require extensive setup time increase retail labor cost. One client reduced store install time from 18 to 6 minutes per unit after switching to our color-coded, tool-free design.

Shipping Damage: Transit damage at 5–10% on large orders translates to serious losses. We provide ISTA drop-tested packaging to minimize this risk, especially for international shipments.

Handling & Storage: Displays that don’t stack, palletize poorly, or exceed shelf footprints can drive up logistics costs. Our team offers early-stage container planning and stack testing to ensure warehouse compatibility.

These factors rarely show on quotes from POP display companies—but they matter.

Customization: Strategic Asset or Cost Trap?

In wholesale procurement, not all customization adds equal value. Consider these distinctions:

High-Value Customization: Modular signage, interchangeable trays, and multipurpose layouts can future-proof a retail POP display. We designed a custom POP display for a South American wine brand that accommodated five bottle sizes—cutting SKUs by 60%.

Low-Value Customization: Small dimensional tweaks on short runs (<500 units) may trigger new tooling, inflating unit cost. In these cases, we suggest pre-engineered solutions with localized graphics to preserve visual identity affordably.

Design-to-Cost Support: Yishang Display supports “design backward from budget” discussions—structuring pop display design around the buyer’s regional logistics, store layout, and campaign timing.

What Buyers Should Know from the Manufacturing Side

Tooling Amortization: New jigs or molds range from $1,500–$3,000. Spread over 500 units, this adds ~$6/unit; over 5,000, just $0.60. Strategic buyers plan batch sizes accordingly.

Compliance & Certification: We provide ISO 9001 certification, RoHS compliance, and ISTA 3A packaging validation. These reduce customs friction and retail chain acceptance risk—critical for buyers in the USA, EU, and Australia.

Batch Optimization: Combining POP signage with custom retail POP display structures in one production cycle reduces overhead and shipping by 15–20%. For buyers coordinating regional campaigns, this consolidation strategy yields real ROI.

How to Evaluate POP Display Value Beyond Price

Use this framework when comparing suppliers or pop display manufacturers:

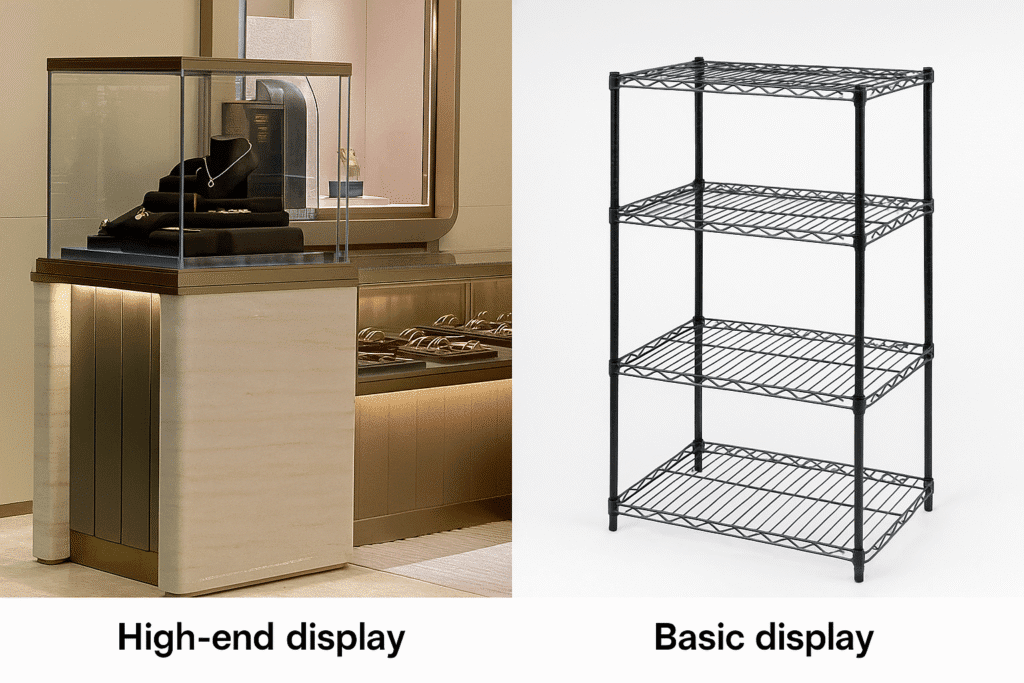

| Metric | High-Capability Display | Basic Budget Display |

| Display Lifespan | 12–36 months across locations | 1–3 months, single campaign |

| Brand Integration | Fully branded, custom POP display | Generic or lightly branded |

| Assembly Method | Tool-free, pre-assembled | Multi-part manual setup |

| Compliance Package | CO, RoHS, ISO, export-ready | Often missing documentation |

| Long-Term ROI | Lower cost per impression | Frequent replacement increases cost |

This table helps align the selection process with the procurement goal—not just checking specs, but ensuring supply chain and brand alignment.

Final Thoughts: Why Wholesale Buyers Choose Yishang Display

Cost-effective POP displays aren’t about finding the cheapest unit. They’re about sourcing the right solution across design, compliance, and delivery. When buyers ask “what is a POP display worth?”, we respond with this: its worth lies in how consistently it drives in-store execution.

Yishang Display offers scalable POP display manufacturing, including corrugated, acrylic, and metal-based designs. We support bulk orders with tailored design-to-cost support, regulatory documentation, and logistics coordination.

Let’s explore a POP display solution tailored to your region, volume, and retail goals. Contact our team to start planning.

Frequently Asked Questions (FAQ)

Q1: What factors affect the cost of a POP display for bulk orders?

A: The key cost drivers include materials (cardboard, metal, acrylic), display type (floor stand, countertop, endcap), design complexity, customization, and shipping format. For example, flat-packed displays lower freight cost but may increase in-store assembly needs.

Q2: How can I reduce the total cost of ownership when sourcing POP displays internationally?

A: Focus on lifecycle performance, batch optimization, compliance readiness (RoHS, ISO), and working with a POP display supplier who provides tooling amortization and drop-tested packaging. Yishang Display offers knock-down designs that reduce container space by up to 35%.

Q3: What’s the typical lead time for custom POP display manufacturing?

A: It depends on design complexity and volume. Typically, we offer prototypes within 7–10 working days, and bulk production within 4–6 weeks. Export documentation (CO, CI, PL) is provided for smooth customs clearance.

These FAQs summarize the key concerns of international wholesale buyers and help support informed decision-making.