Rethinking Efficiency: What Procurement Means for Today’s Global Display Buyers

For overseas wholesale buyers sourcing floor standing units (FSUs) or free standing display units (FSDUs), procurement today is less about finding the lowest cost and more about minimizing risk, maintaining brand standards, and achieving speed-to-market. Display units serve as strategic retail assets—affecting visibility, planogram alignment, and shopper engagement at the point of sale.

Efficiency now includes rapid prototyping, modular engineering, material compliance, and freight efficiency. Our team provides integrated solutions from concept validation to multi-market rollout, ensuring each program supports your cost, time, and performance benchmarks.

Why FSUs/FSDUs Pose Unique Sourcing Challenges for Wholesale Buyers

FSUs and FSDUs are highly customized retail tools that must balance structural integrity, brand expression, and transport cost. For wholesale procurement, the variables are complex: product weight, in-store traffic, geographic standards, and branding consistency.

One beverage distributor we work with needed a floor display stand that held 60+ kg per unit, shipped flat, and included anti-slip feet for polished store tiles. Projects like this highlight why sourcing these units demands engineering and supply chain foresight—not just manufacturing.

These display solutions often use steel frames, MDF for printable panels, and acrylic for visual elements. A modular display stand for trade marketing ensures flexibility across campaign types without needing a complete structural redesign. Poor planning around materials impacts not only strength, but freight class, customs clearance, and even recyclability compliance in some markets.

What to Finalize Before Asking for a Quotation

To ensure quotes are accurate and projectable, wholesale buyers should clarify four core areas.

1. Load and Structural Needs

Load capacity per tier (e.g., 30 kg/shelf)

Anti-tip stability in public areas

Panel removal or replaceable headers

2. Materials and Finish Options

Cold-rolled steel or aluminum frame

Plywood or MDF for branding surfaces

Acrylic or PETG for signage zones

3. Brand Consistency Requirements

Color codes (Pantone or RAL references)

Print type: UV, screen, or vinyl

Surface treatment (gloss, matte, textured)

4. Deployment Environment

Climate, flooring material, and setup location (in-store or warehouse)

Skipping these steps often leads to misalignments between expectations and supplier output, increasing rework and delays.

Translating Creative Design Into Engineering Logic

Procurement teams often inherit creative designs that ignore manufacturing constraints. We assist clients in translating concepts into mass-producible formats through iterative prototyping and structural feasibility checks.

For example, we may suggest a slot-and-tab joinery system instead of full welding to reduce tooling costs and simplify flat-pack configuration. We also simulate load stress on key joints to validate product safety.

Our engineering teams optimize for:

Standardized shelf dimensions

Reinforced base panels

Modular add-ons for multi-brand use

Packaging Strategy: Reducing Freight Without Sacrificing Integrity

Every project includes a dedicated packaging strategy. With flat-packable metal POS displays, clients often save up to 35% in international freight costs. These flat-pack retail fixtures for export minimize shipping volume while maintaining integrity, using pre-labeled packaging and simplified component kits for quick setup.

MOQ and Batch Flexibility for Global Buyers

We understand global buyers often juggle multiple launch cycles, limited warehousing, and cost sensitivity. That’s why our batch production approach supports small trial runs and phased high-volume execution.

Most clients request variations on a shared frame to simplify configuration and maintain consistency. This helps lower per-unit cost and shortens tool-up time.

| Order Volume | Base Modular Stand | Fully Custom Unit | Lead Time |

|---|---|---|---|

| 100 pcs | $79 | $112 | 30–35 days |

| 500 pcs | $58 | $87 | 26–30 days |

| 1000+ pcs | $45 | $76 | 21–25 days |

We provide clear unit cost structures, helping buyers present landed cost justifications internally across procurement and finance teams.

Engineering Validation & Risk Control: How to De-Risk Your Order

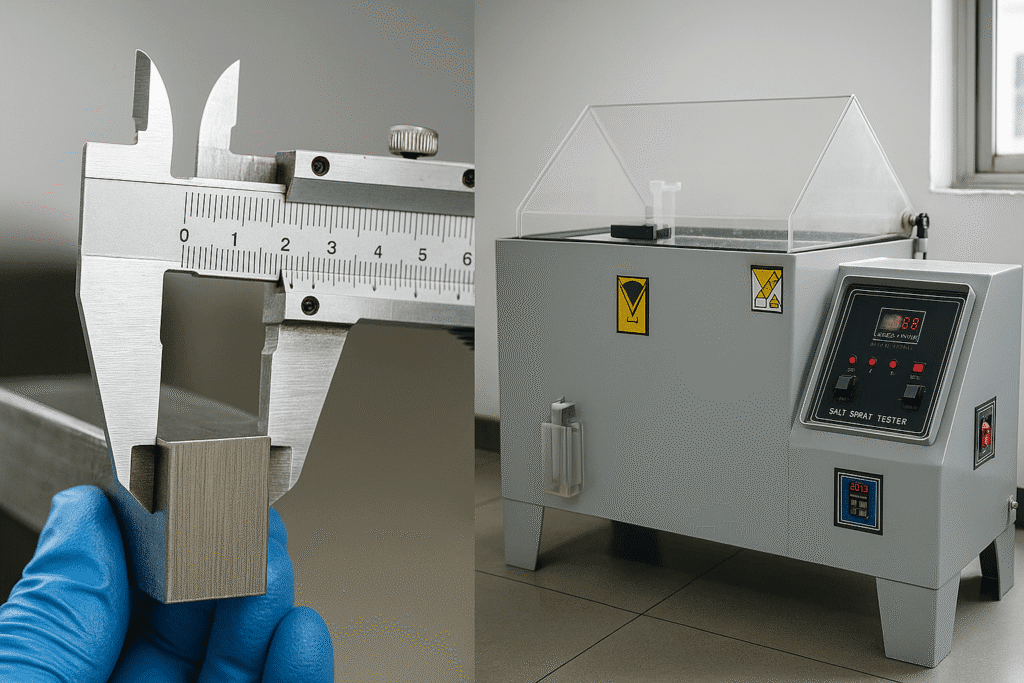

Key risks include unverified material grades, untested finishes, and missing tolerances. We prevent this by providing sample kits, material test certificates, and in-line QA reports.

At our facility, we document material thickness (e.g., 0.8 mm cold-rolled steel), confirm MDF density, and offer:

Salt spray resistance test

Drop and tilt simulation

Flame retardant validation (on request)

All our floor display racks comply with ISO 9001, RoHS, and standard EU/US import protocols. These protocols help avoid clearance issues and provide traceability.

Logistics Optimization: The Often-Overlooked Cost Factor

Many procurement teams focus on unit cost and lead time, but overlook the role of last-mile execution in driving total efficiency. Display units that arrive late, damaged, or poorly labeled often disrupt promotional schedules and inflate operational cost.

Buyers can streamline regional deployment by integrating freight planning into the early stages of production, aided by our structured approach. For example, a Canadian buyer avoided demurrage fees by receiving split shipments sequenced to launch dates, while a UK retail chain reduced unloading time by 40% through destination-specific pallet configuration.

Instead of focusing again on flat-pack benefits, this stage emphasizes deployment efficiency:

We support regional distribution planning tailored to in-store rollouts, sequenced delivery windows by launch geography, and freight labeling aligned with customs and warehouse systems.

Planning for Repeatability: Making Your Display Procurement Sustainable

Rather than treat each order as a one-off, our clients increasingly use a platform-based approach—shared metal structure, adjustable shelving, branded overlays.

In 2023, over 60% of our display programs used shared tooling across multiple SKUs. This allows:

Faster reorders using same tooling

Consistent in-store branding

Lower tooling amortization cost

One South American distributor deployed a common modular base across beverage, snacks, and electronics. Structural variation was under 3%, yet brand segmentation was preserved through header and shelf changes.

Why Efficient Display Procurement Drives Sales and Reduces Waste

FSU and FSDU sourcing is no longer just a supply chain task—it’s part of strategic retail execution. Our technical and sourcing specialists help wholesale buyers align speed, scale, and compliance without compromising visual impact.

Let’s simplify your next rollout—request a quote or sampling plan from our team today. As a trusted metal display stand supplier in China, Yishang Display specializes in scalable, customized export-ready FSDU programs.

FAQs Buyers Often Ask

Q1: Can I start with a small order to test quality before full production?

Yes. We offer low-MOQ sampling with fast prototyping so you can validate structure, branding, and usability.

Q2: Do you provide drawings or visuals before production? Yes. Standard layout drawings and samples are available upon request to support alignment before production.

Q3: How do you ensure the quality of custom metal POS displays? Each unit is built to meet ISO 9001 and RoHS standards and is validated through drop, load, and wear-resistance testing with full documentation.

Q4: What industries do you serve most?

We regularly produce durable retail display stands for beverage, electronics, tools, cosmetics, and promotional products.

Q5: Can you help with retail fixture sourcing in China?

Yes. We offer OEM metal display solutions for global sourcing needs with over two decades of production expertise.