In the tight-margin world of global wholesale, supply chain efficiency is often the difference between profit and loss. For procurement directors and category managers, Retail-Ready Packaging (RRP) is no longer just a box—it is a financial lever that dictates Landed Cost and Vendor Compliance ratings.

While standard corrugated trays suffice for lightweight consumables, they are becoming a liability for heavy-duty retail shelving solutions. As retailers like Walmart and Costco enforce stricter compliance mandates, the failure of packaging translates directly to refused shipments, “unsellable” inventory, and punitive vendor chargebacks.

To safeguard your margins, procurement strategy must evolve. This guide moves beyond basic aesthetics to explore the engineering pillars of effective display systems. We analyze why a strategic migration toward metal display solutions and hybrid materials is often the definitive method for maximizing ROI in global logistics.

Pillar 1: Re-Engineering Structure for Maximum Load-Bearing ROI

The primary metric for any B2B buyer isn’t just unit cost; it’s the failure rate. The journey from a factory in China to a retail shelf in Europe subjects packaging to brutal compressive forces.

The Financial Risk of Low-Grade Materials

Many sourcing strategies fail by balancing cost against load-bearing capacity using outdated metrics like the Edge Crush Test (ECT). While ECT works for chips, it is disastrous for industrial goods.

- The Creep Factor: Under sustained weight (e.g., motor oil, tools, beverages), cardboard fibers buckle over time. This is a physical inevitability of cellulose materials.

- The Consequence: “Elephant foot” collapse leads to unstable pallets and safety rejections at distribution centers. If a pallet leans more than 5 degrees, many automated warehouses will reject the entire truckload.

The Engineering Solution: Metal vs. Cardboard

This is where custom retail display manufacturer expertise becomes critical. By utilizing carbon steel and iron wire, we eliminate material creep.

- Tensile Strength: Metal components maintain 100% rigidity regardless of load duration.

- Hybrid Efficiency: Replacing a 5-layer corrugated divider with a 3mm steel wire frame can increase load capacity by 400% while reducing volume.

This isn’t just about strength; it’s about protecting your Vendor Scorecard. A product that arrives perfectly stacked is a product that gets reordered.

Material Comparison: Choosing the Right Substrate for Your SKU

| Feature | Standard Corrugated (ECT 32-44) | Yishang Metal / Hybrid Solution |

|---|---|---|

| Load Capacity | Low (5-15kg per shelf) | High (50kg – 150kg+ per shelf) |

| Humidity Resistance | Poor (Loses 50% strength at 90% RH) | Excellent (100% Retained Strength) |

| Lifespan | Single-use (Weeks) | Semi-Permanent (Years) |

| Tooling Cost | Low | Moderate |

| Cost Per Use | High (Recurring repurchase) | Low (Amortized over refills) |

| Best Application | Snacks, Cereal, Light Home Goods | Auto Parts, Tools, Beverages, Electronics |

Pillar 2: Logistics Math and Cubic Efficiency (CBM)

In wholesale distribution, shipping “air” erodes margins. Supply chain optimization is a fundamental design imperative that directly impacts your Landed Cost.

The Multiplier Effect of Intelligent Knock-Down (KD) Design

Rising freight rates demand smarter engineering. The most effective lever is Intelligent Knock-down (KD) design. Many suppliers claim “flat-pack” capability, but complex folding often compromises rigidity. True engineering excellence lies in specific ratios:

- Volume Reduction: A pre-assembled automotive display might fit only 20 units per 40ft container.

- KD Optimization: Using modular metal components with snap-lock fittings, Yishang Display can often fit 200+ units in the same space.

The Result: A 90% reduction in freight cost per unit. In high-volume scenarios, the savings in ocean freight often completely offset the higher manufacturing cost of the metal fixture vs. a cardboard alternative.

Precision Sizing to Eliminate the “Air Tax”

Integration of product dimensions into the RRP unit requires mathematical precision.

- Pallet Overhang: Causes damage and carrier surcharges.

- Pallet Underhang: Wastes valuable floor space.

By adjusting a metal rack’s width by a mere 5mm during the display and packaging design phase, we can align master cartons perfectly with standard GMA (US) or Euro pallets. For high-volume buyers, a 5% improvement in container loading efficiency translates to tens of thousands of dollars in annual savings.

Pillar 3: Mastering Retailer Compliance and Labor Economics

Retailers have codified their standards into the “5 Easys”: Easy to ID, Open, Stock, Shop, and Dispose. Failure to meet these results in operational friction and financial penalties.

The “Knife-Free” Mandate: Improving Vendor Status

Modern supply chains are aggressively adopting “Knife-Free” protocols to enhance safety and reduce product damage.

- The Problem: Taped boxes require cutters, risking injury and damaged inventory.

- The Solution: Industrial-grade metal RRP utilizes open-front wire designs.

Safety as a Feature: Compliance extends to the finish. As a responsible partner, Yishang Display ensures all welds are deburred and finishes are RoHS compliant. This risk mitigation ensures your products face no barriers to entry in strict regulatory markets like the EU.

Velocity Economics: The Cost of Replenishment

Store managers evaluate vendors based on replenishment speed.

- Slow: 15 minutes to assemble a complex cardboard bin = Labor Liability.

- Fast: <60 seconds to roll a pre-loaded metal rack to the floor = Strategic Asset.

For heavy, high-velocity goods, a rolling metal rack essentially subsidizes the retailer’s labor cost. This is a powerful negotiation point for category managers seeking premium placement.

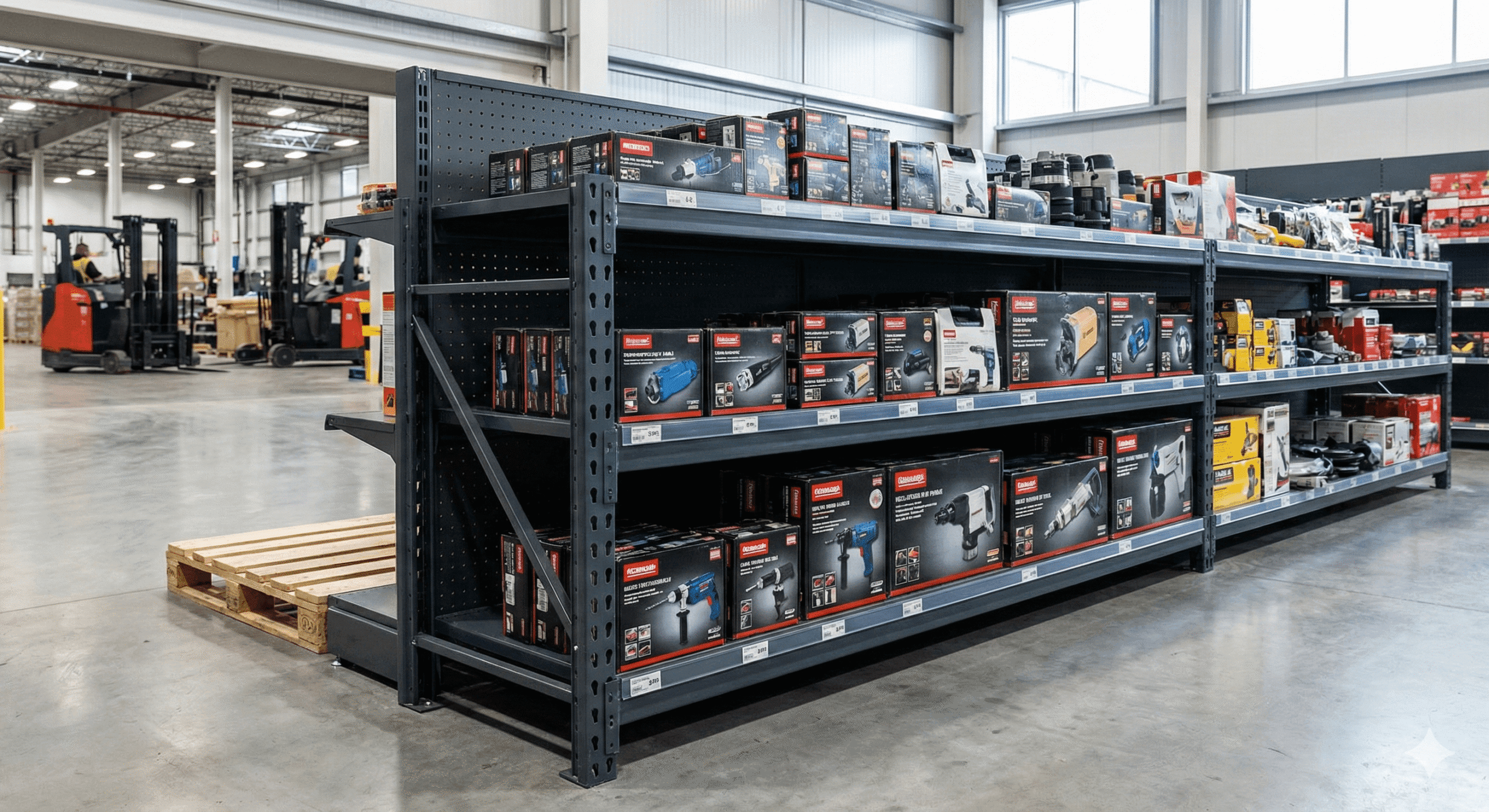

Pillar 4: Strategic Shelf Dominance and Shopper Psychology

On the sales floor, the synergy between structure and marketing is paramount. Your packaging must function within planogram constraints while maximizing visual impact.

Strategic Placement: Integrating POP & POS

Understanding pop vs pos displays is about budget allocation.

- Point of Purchase (POP): Broad marketing.

- Point of Sale (POS): The transaction zone.

B2B buyers should leverage RRP as a hybrid. A durable counter shipper display serves as a bulk shipping vessel and a premium POS fixture. This dual utility reduces total spend. Accuracy is Key: A display that is 0.5 inches too wide will be rejected by the planogram team. We engineer fixtures that maximize internal facing area while strictly respecting external boundaries.

The “Premium” Gap: Visual Merchandising

Shopper psychology links display stability with product quality.

- Low Perception: High-value tools in tearing cardboard bins.

- High Perception: Products in rigid, powder-coated metal units.

Metal RRP allows for advanced mechanics like spring-loaded pushers, ensuring the shelf remains “faced.” By investing in semi-permanent structures, you reduce the labor required for store staff to tidy the aisle, addressing your target audience’s needs for a clean shopping experience.

Pillar 5: Prototyping and Validation (The OEM Advantage)

The gap between a CAD drawing and physical reality is where budget overruns happen. Validation is your insurance policy.

Rigorous Testing Protocols (ISTA Standards)

Before mass production, we advocate for empirical testing mirroring ISTA (International Safe Transit Association) standards.

- Vibration Testing: Simulates truck chassis harmonics to ensure welds hold over thousands of miles.

- Compression Testing: Validates that bottom units support dynamic pallet loads without deformation.

- Salt Spray Testing: Guarantees corrosion resistance for global shipping.

Partnering with an OEM that performs these tests internally prevents the nightmare scenario of a 100% failure rate upon arrival.

Pillar 6: Lifecycle Strategy and Circular Economics

Global pressure for sustainability is pushing supply chains toward circular models. Buyers must now consider the setup breakdown and disposal costs.

The ROI of Returnable Assets: A Financial Case Study

For closed-loop supply chains, reusable packaging is the gold standard. Let’s look at the math for a hypothetical tool brand deploying to 500 stores over 3 years:

- Scenario A (Disposable Cardboard):

- Cost per unit: $20

- Replacement rate: Every month (durability failure)

- Total 3-Year Cost: $20 x 36 months = $720 per store

- Scenario B (Yishang Metal Permanent Display):

- Cost per unit: $100

- Replacement rate: Every 3 years (high durability)

- Refurbishment cost: $20

- Total 3-Year Cost: $120 per store

The Financial Impact: While the initial CapEx is higher ($100 vs $20), the Metal RRP delivers a 500% ROI over the lifecycle. Furthermore, utilizing zero-VOC powder coatings aligns your brand with global sustainability mandates, protecting you from future environmental taxes.

Frequently Asked Questions (FAQ)

Q: What is the main difference between Retail-Ready Packaging (RRP) and Shelf-Ready Packaging (SRP)? A: The terms are often used interchangeably. However, SRP typically refers specifically to the unit sitting on the shelf (often cardboard trays), whereas RRP is a broader term encompassing the entire system, including pallet displays, rolling racks, and bin displays that arrive ready to sell with minimal setup.

Q: Why should I choose metal RRP over corrugated cardboard for my products? A: Metal is superior for products that are heavy (over 10kg), high-value, or high-velocity. It offers significantly higher load-bearing capacity, resistance to humidity (crucial for ocean freight), and better aesthetic presentation for premium brands.

Q: Does Yishang Display offer custom design services for specific SKUs? A: Yes. As an ODM/OEM manufacturer, we reverse-engineer the display based on your specific product dimensions and pallet requirements to maximize shipping density and ensure planogram compliance.

Q: How do you handle international shipping compliance for metal displays? A: We ensure all designs are optimized for standard shipping containers and pallets. Our finishes are RoHS compliant, and we can conduct ISTA testing to ensure the packaging survives global transit.

Conclusion: Partnering for Supply Chain Excellence

In the modern retail landscape, packaging is an engineering challenge, not just a printing job. For categories that are heavy, bulky, or high-value, reliance on traditional materials is a calculated risk that often fails.

To optimize your Landed Cost and Vendor Scorecard, you need a partner who understands the nuances of metal fabrication, load dynamics, and international freight.

Yishang Display brings over 26 years of OEM expertise to these challenges. We don’t just build racks; we engineer supply chain solutions.

Ready to optimize your retail display strategy? Contact our engineering team today for a structural audit and quote.