Introduction: More Than a Stand — Why Wholesale Buyers Choose Strategic Pedestal Design

Wholesale buyers evaluating display fixtures are not just looking for form. They need function, scale, consistency, and supplier reliability. At Yishang Display, we understand that pedestals are not merely aesthetic enhancements; they are tactical tools across sectors like art curation, retail visual merchandising, and exhibition production.

This article breaks down how wooden display pedestals and acrylic displays function as commercial assets. You’ll find insights into materials, production specs, application scenarios, and how we tailor OEM/ODM solutions for B2B clients worldwide.

I. The Spatial Logic of Effective Product Display

Pedestals organize space and narrative. In retail or gallery settings, spatial psychology plays a measurable role. One study (MuseumNext, 2023) found that merchandise placed at a 95–120 cm height range saw a 32% higher engagement rate. This is why proper wood stands for display or acrylic support desks are never random—they are engineered for visibility and flow.

Wooden pedestals, especially when integrated with organic tones or branded stains, offer visual solidity. They’re ideal for boutique retail or cultural collections. Our clients in France use wooden store displays to introduce curated wine bottle collections. Meanwhile, acrylic standee bases provide transparency that blends into modern environments, used widely in electronics showrooms or minimalist exhibits.

For merchandising in high-traffic zones, pedestal placement can direct movement and impact dwell time. Our display planning includes structure, height, and customer behavior mapping—because strategic display enhances sales outcomes.

II. Comparing Material Intelligence: Wood vs. Acrylic

Material matters. Buyers sourcing in bulk for global rollouts or museum installations must evaluate performance and adaptability.

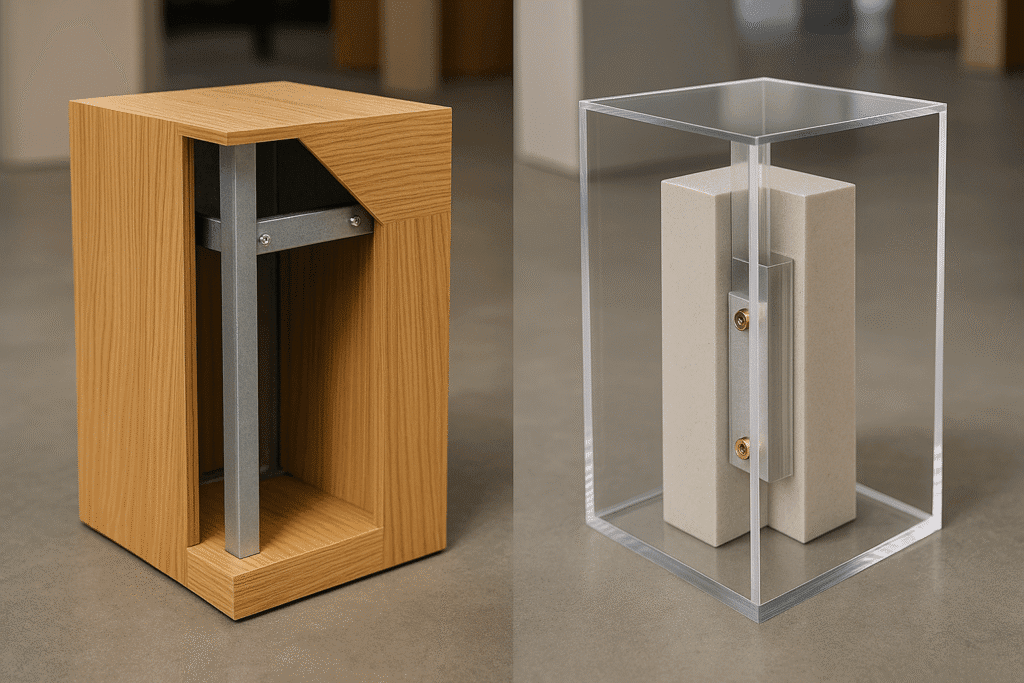

Wooden displays offer structural strength and longevity. Yishang’s pedestal bases integrate internal metal support frames that ensure stability under high-load conditions—supporting up to 250kg per unit. We use precision-welded steel joints inside MDF-core structures to eliminate shift during transport and repeated usage. These frames are treated with anti-corrosion powder coatings, extending product lifecycle in humid or transit-heavy environments.

They’re ideal for wood display racks for retail, or modular wood nesting tables for retail display that require both rigidity and interchangeability. Finishes include matte black oak veneer, ash laminates, and anti-scratch topcoats.

Acrylic displays—constructed from solid PMMA—provide 90%+ light transmission and excellent UV stability. They’re widely used in cosmetics, fashion accessories, and consumer electronics. For instance, a U.S. brand used our custom acrylic display boxes for sneaker promotions, applying LED-embedded metal footings for added visual framing.

We advise on the optimal integration of metal fasteners or steel base plates inside acrylic for added load support without compromising clarity. All acrylic products follow strict machining tolerances for seamless assembly in mass production.

Every client receives production drawings and factory samples because consistency across 1000+ units is non-negotiable in B2B orders.

III. How B2B Clients Choose: Function, Fit & Fulfillment

Your selection depends on usage context, structural requirements, and your supply chain strategy.

A client in Qatar’s luxury furniture sector chose deep walnut custom wood displays with embedded steel mounts for sculptural vases. Another client in Korea ordered 3,000 acrylic organizer trays with reinforced edges for electronics displays.

Recommended configurations include:

For vibration-sensitive or heavy loads: MDF with full welded inner frames and surface-mounted base plates.

For temporary or mobile displays: Lightweight acrylic with stainless connectors and flat-pack kits.

For prestige: Floating acrylic jewelry display cases with brushed aluminum accents and hidden fixings.

Yishang Display manufactures with complete traceability—from raw material to packaging. As a certified ISO 9001 and RoHS-compliant supplier, we support OEM/ODM designs with:

Steel machining (cutting, bending, laser welding)

Aluminum profile fabrication

CNC for wood and acrylic

In-house powder coating & anti-rust finishes

Our 8,000 m² facility produces over 10,000 units annually. We support:

MOQ from 100 units, scalable to 10,000+

Sampling within 7–10 days

Custom logistics: mixed containers, port documentation, and inspection certifications

We’re not a drop-shipper. We’re a vertically integrated metal and display structure manufacturer who engineers for stability, repeatability, and shipping resilience.

IV. Industry-Specific Application & Strategic ROI

We serve over 12 sectors. Here’s how real clients integrate our pedestal systems:

Museums: Fire-rated MDF paired with welded metal internal brackets for secure artifact display. One EU client used 120 pedestals—identical dimensions—to create uniform exhibition flow.

Fashion Retail: Brands deploy acrylic earring stands and acrylic ring displays with steel support plates hidden beneath translucent bases. These are common in duty-free shops and mall boutiques.

Hospitality & Food: Cafés use wooden flight boards with stainless handles. Bars deploy bar caddy wooden trays with steel dividers to hold product samples cleanly and securely.

Trade Shows: At a U.S. expo, one client used 800 region-customized acrylic standees custom with aluminum crossbars for durability and reuse. Flat-pack assembly supported quick setup.

We align our build quality to your ROI expectations: from ease of transport to brand image consistency, your pedestal system becomes an asset—not just a support.

FAQ: Quick Answers for Procurement Teams

Can I order fewer than 200 units?

Yes, MOQ starts at 100 pcs depending on spec and finish complexity.

Do you offer metal reinforcement inside wood/acrylic products?

Absolutely. We offer internal frames, base plates, or hidden brackets for heavy-duty or modular displays.

Can I request a sample before mass production?

Yes. We offer pre-production samples with exact material and weld finishing.

What’s your warranty or damage policy?

Yishang provides replacement or partial refund on verifiable factory defects or transport-damaged goods.

Is your factory capable of branding and documentation compliance?

Yes. We provide branding, labeling, customs-ready documentation, and third-party inspection support.

Conclusion: Choose the Pedestal That Supports Growth

In display, structure dictates impact. Yishang Display combines the strength of metal fabrication, the flexibility of acrylic forming, and the warmth of wood finishing into a single integrated production solution.

Whether your priority is load-bearing structure, transport efficiency, or upscale visibility—we build with industrial logic and market reality.

With over 26 years of production expertise and clients in 50+ countries, we don’t just supply—we support.

Start your quote today—our team will return within 24 hours with a tailored solution.